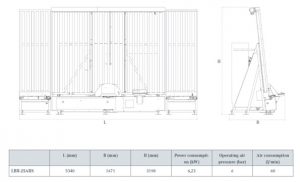

LBH ARS

Fully Automatic Butyl Application System

Sensor-controlled guide rollers stabilize the profile and ensure even butyl application. The integrated input and outlet stations at the front and rear of the machine enable the processing of aluminium frames up to a maximum size of 2500 x 2500 mm with the standard version.

Thanks to the user-friendly interface of the control panel, the most diverse corner formations of plugged or bent (radius)frames can be adjusted precisely and displayed on the screen.

The automatic detection of the spacer width on the feed table, as well as of the profile material (aluminium or stainless steel, see ‘Optional’) ensures fully automatic and extremely precise positioning of the butyl nozzle to the frame.

The LBH-25ARS is able to apply butyl to spacer bars with integrated Georgian bars / muntins in perfect quality. This is guaranteed by integrated optical sensors that detect the exact bar / muntin position and by holding-down rollers positioned obliquely above the exterior of the frame profile.

Highlights

- Processing of all kinds of spacer frames with and without Georgian bars / muntins

- Integrated lfting fingers support the frames when they are pivoted

- Butyl is evenly distributed on both sides

- Compact design with horizontal material pressing system

Optional

- Nozzle block that can be lifted and lowered (for different radii in the corners), especially for processing stainless steel profiles

- Processing of frames up to a size of 3500 x 2500 mm with and/or without manual help (subject to the profile type and/or the type of lifting finger selected)

- Two additional lifting fingers (for processing larger frames)