FPS-US

Automated Gas-Filling Machine

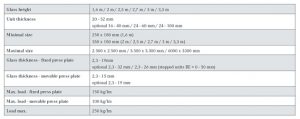

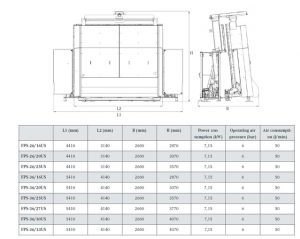

This is a fully automated system for gas filling, assembly and pressing of insulating glass units. The tried and tested system of filling the sealed ‚chambers‘ with gas from the bottom up reduces turbulence to zero. A system developed by LiSEC, with ‚separate chambers‘ and sealing bars that adjust to the length of the glass unit, precisely meters the amount of gas needed and minimizes gas consumption.

The upstream measuring zone transfers the data to the gas-filling press, which then adjusts by means of a spindle drive and presses the glass units according to the data measured. The measuring zone furthermore calculates the volume of the glass unit to be able to pre-meter the gas amount needed and to optimize gas consumption. The gas mixing ratio can also be precisely adjusted.

Highlights

- Suitable for filling argon, xenon and krypton

- Unique gas-filling rate Gas filling without turbulence

- Movable sealing bars significantly reduce the loss of gas

- Cycle time is independent of the glass length (by filling gas from the bottom up)

- No excessive pressing required thanks to the upstream measuring zone

- Versions for double and triple insulating glass units

Optional

- Shapes according to LiSEC shape catalog

- Stepped units

3-side stepped unit:

BE = 0 mm, LE + RE + UE = 0 – 140 mm

4-side stepped unit:

BE = 0 – 50 mm, LE + RE + UE = 0 – 140 mm

BE = 0 – 100 mm, LE + RE + UE = 0 – 140 mm

BE = 0 – 100 mm, LE + RE + UE = 0 – 200 mm

Available software

GPS.lineserver