BMS

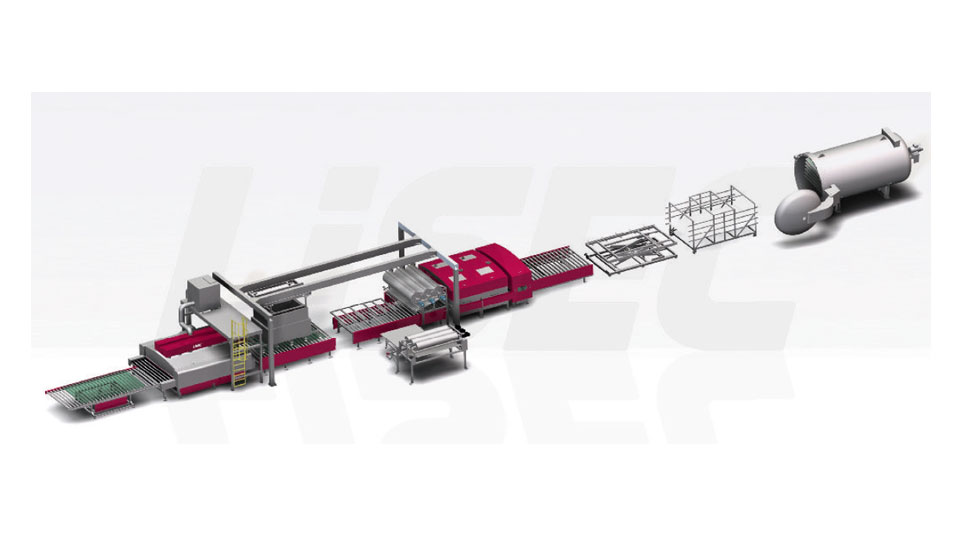

Lami-line combined to Low pressure autoclave

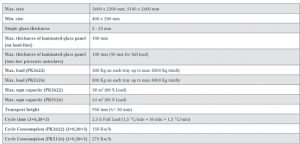

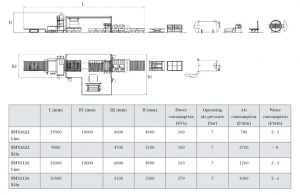

Laminating glass plant specifically designed for cut to size/miscellaneous production and tempered/toughened glass processing.

Pre-lamination equipment is integrated on this configuration for achieving the same quality results as standard laminated glass plant processed by high pressure autoclave. It includes one set of nip roller system with forced air convection furnace and press with anti-torsion system.

Suction cups transfer for glass assembly. Rack for trays loading into the kiln. Forced air convection heating system and increased pressing force ensure a perfect quality finished product

Highlights

For refrigerated or interleaved PVB, EVA and ionomer interlayers such as SentryGlas..

Fast cycle times and easy glass handling comparing to manual vacuum laminating solutions through automatic squaring

system and semi-automatic suction cups transfer.

Pre-lamination line can be customized with the desired automations.