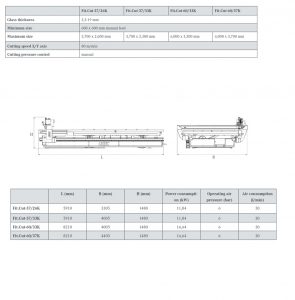

FitCut-K

The compact all-rounder for straight and shaped cuts on glass

With the compact all-rounder FiT.Cut, you are perfectly prepared to meet all modern cutting needs. Both straight and shaped cuts on fl at glass can be made with minimum tolerances and maximum precision. The cutting machine‘s tilt function ensures added flexibility.

The FiT.Cut‘s base is made of steel and comprises a hydraulic tilting part and a stationary part, the latter being provided with a cutting bridge. Therefore the cutting bridge remains in the horizontal position while the tilting part moves, and is not subject to redundant vibrations. Accordingly, the load placed on the tilting part is significantly reduced. The FiT.Cut automatically detects the glass edge, and therefore stock sheets do not have to be aligned manually against front positioning stops.

The cutting bridge, which rests on a toothed rack guide with multi-axis central cutter, is driven synchronously by two servo motors, one on each side, guaranteeing minimum cutting tolerances and longevity of the machine. A travel path optimization function ensures very short travel distances of the axes, allowing for an extremely short duration of the cutting process. If a glass sheet breaks or there is an incorrect measurement, a sensor automatically stops the cutting process in order to protect the machine from any damage.

Highlights

- Compact, tiltable all-rounder for straight and shaped cuts

- Minimum cutting tolerances and longevity

- Torsion- and vibration-free guide and drive element

Optional

- Glass thicknesses of up to 19 mm

- Edge deletion on Low-E glass, either up to 20 mm or up to26 mm

- Simple cutting optimization GPS.hand – FiT Optimizer

- Integrated breaker bars

- Auto-scanning system (scanning of any kind of shape)

- Second oil supply unit

- Equipment for tropical conditions

Available software

LIS.hand GPS.mon