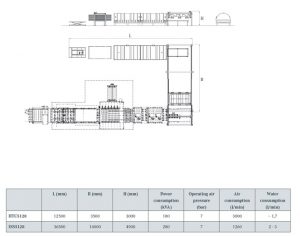

ISS LINE WITH TUNNEL

Automatic lami-line with tunnel system

This plant composed by pre-lamination line, climatic room and laminating tunnel is the best solution for mix production, cut to size laminated glass production, and specifically for tempered laminated glass.

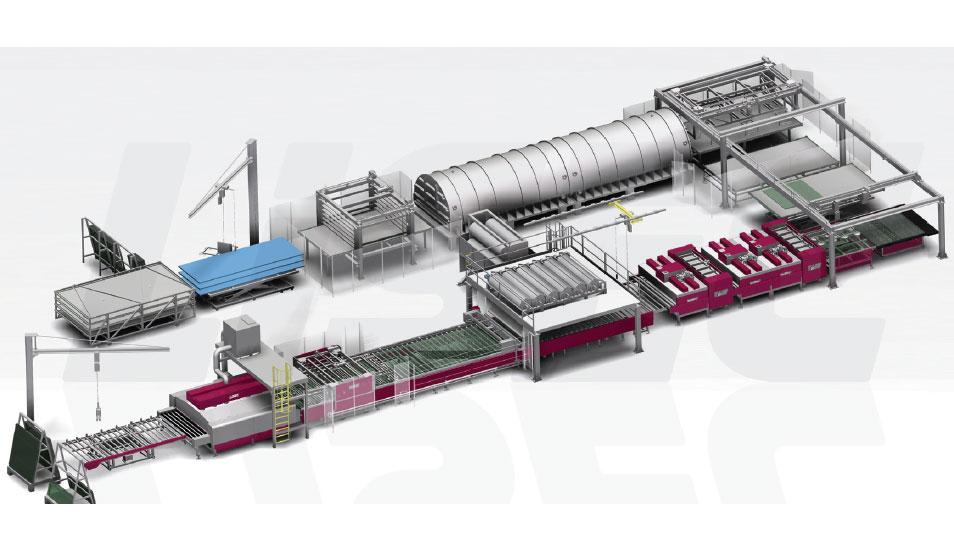

Laminating tunnel, based on continuous process, achieves very fast cycle time and, as a consequence, a very flexible production.

Highlights

Forced air convection system fitted on heating tunnels guarantees perfect heating process for low-e, so_ coated or printed glass.

Anti-torsion system on each nip roller applies uniform pressure along the entire widths.

Laminating Tunnel is arranged for standard PVB (interleaved or refrigerated), EVA and ionomer interlayers such as SentryGlas

®, guaranteeing the same quality results of finished product as those ones obtained by using a high pressure autoclave.

Tunnel revolutionary concept to separate the heating from the cooling process ensures considerable energy savings.

Tunnel equipped with fully automatic loading device and storing system : no operator is needed during night cycles to load and unload racks.

Horizontal glass processing for ensuring the best glass load optimization.