LBH 60M

Semi-Automatic Butyl Coating Machine

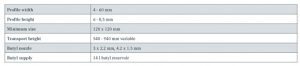

The LBH-60M high-precision butyl coating machine is designed to evenly coat both sides of spacer frames with butyl. An integrated measuring device measures the frame widths and ensures that the nozzles are continuously adjusted from 4 to 60 mm.

When processing rectangular shapes, sensor-controlled hold-down rollers stabilize the frame to ensure an optimum coating quality. Even circles, shapes and frames with Georgian bars / muntins can be easily coated using the LBH-60M. To facilitate processing of shapes, the hold-down rollers can be deactivated, if required. Thanks to the vertical lifting unit, the machine’s

working height can be easily adjusted to fit the operator, and according to the frame size.

By means of a clear graphic display on the screen, different forms of butyl application in the frame corners (butyl string) can be set. The speed of the transport belt can be adjusted individually via the keypad on the control panel. For a constant andoptimum coating quality, parameters automatically adjust to the set speed.

The position of the butyl unit enables shortest butyl refill times. The machine is equipped with an integrated week timer to be able to preheat the butyl after longer production shutdowns.

Continuous adjustment to frame width Equipment for manual processing of round arches

Highlights

- Even coating on both sides of the frame

- Continuously adjustable working height

- Easy operation

- Processing of spacer frames with Georgian bars / muntins

- Easy coating of round arches and shapes