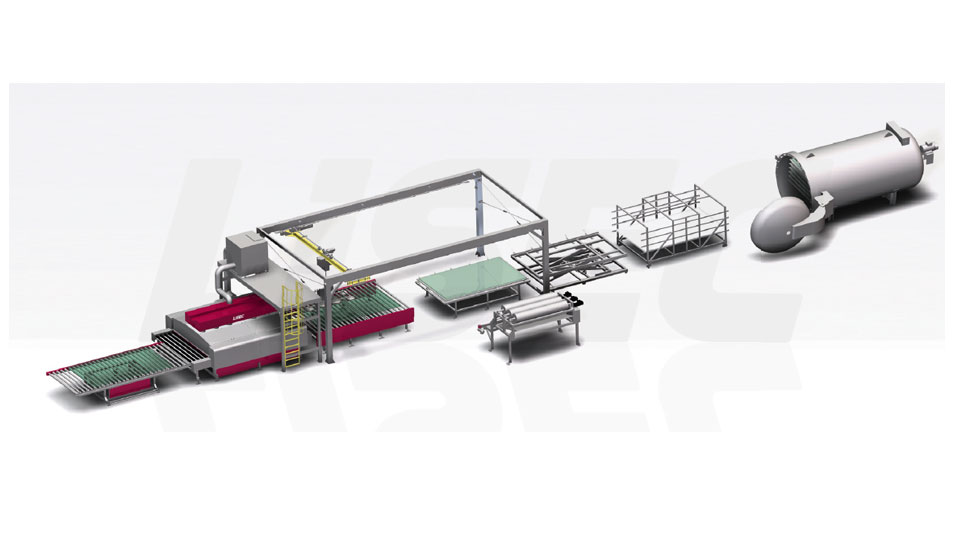

MMS LINE

Lami-line combined to Low pressure autoclave

Complete entry level laminating glass production line for high-quality fi nished products.

Including tilting table, horizontal washer, assembling conveyors and crane suction cups system, PVB/EVA unwinding and cutting system, climatic room, tray with vacuum silicone blanket, scissor lift , storing rack, low pressure autoclave.

Glass is assembled over a tray with a silicone blanket to enable vacuum process, then it is loaded horizontally into the kiln with the help of a scissor lift and a rack with wheels.

Highlights

For refrigerated or interleaved PVB, EVA and ionomer interlayers such as SentryGlas®.

Long-life silicone blankets ensure a cost effective solution comparing to traditional disposable bags normally used in vacuum process within high pressure autoclave.

Optimum ratio among output – energy consumption – investment.