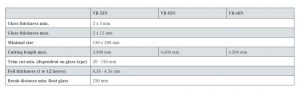

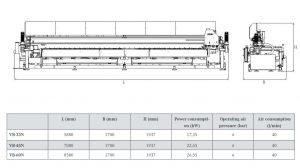

VB-N

Automatic Cutting Table for Laminated Glass

Precision cutting machine for laminated glass, which can be combined with an upstream positioning bridge designed to automatically feed glass sheets. Stretching and separation of the PVB foil are carried out by suction cups operating from below. This technology guarantees that coatings are well protected against damage during cutting. Thanks to its movable design, the cutting bridge with clamping system can automatically separate trim cuts with a width from 20 to 150 mm (both on the front and rear sides of laminated glass sheets). The trim cuts are automatically removed and disposed of in a container. The combination of a high-precision cutting technology and an optimized electronic control system, as well as the use of a mechanical foil separation system offer unrivaled precision and edge quality of the glass and PVB layers, even of thick glass units and using special foils. Glass positioning for straight cuts is supported by a laser.

Highlights

- Fully automatic thermal and mechanical separating process

- Automatic separation of trim cuts with a width from 20 to 150 mm on the front and rear sides

- PVB foil thickness: up to 12 layers

- Also suitable for cutting float and cast glass

Optional

- Float glass breaking up to 19 mm

Available software

GPS.hand GPS.mon