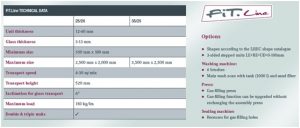

FIT LINE-3

FiT.Line 3

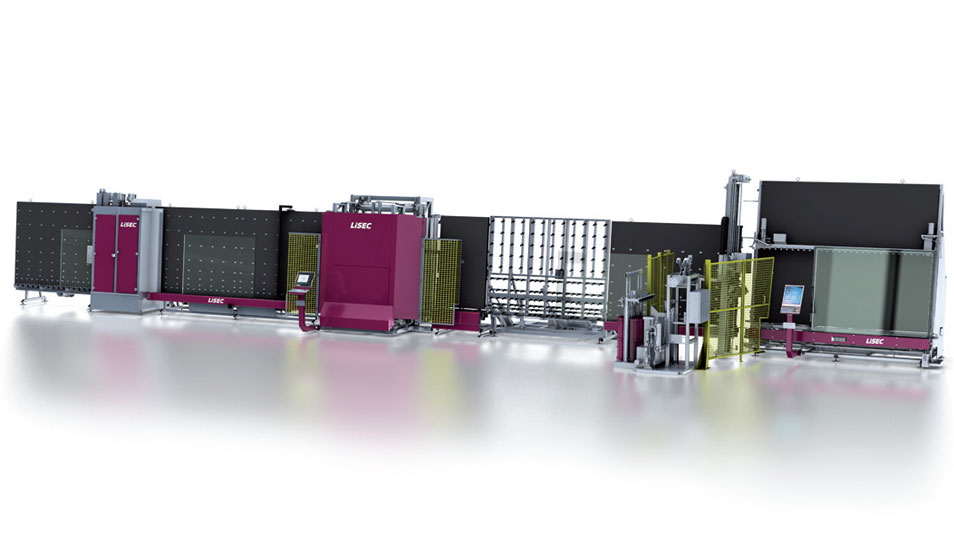

The manufacturing line with integrated roller table for maximum flexibility

The perfect manufacturing line for high-quality and durable insulating glass production. The integrated roller table placed in front of the sealing machine makes it possible to send out units and seal them manually or process them individually.

Total length:

FiT.Line 3 (25/20): approx. 21.5 m; FiT.Line 3 (35/25): approx. 27.4 m

Machine components

n Washing machine

n Frame mounting station

n Automatic assembly press/

gas-filling press

n Roller tilt table

n Automatic sealing machine

(shape data to be input manually)

Advantages that speak for themselves!

???? Plug & produce: The all-in-one system for insulating glass production is

perfectly adopted to your needs and easy to operate.

???? Fast delivery & installation

???? Production of double and triple glazings (shapes and 3-sided stepped

units can be added as an option)

???? High quality production using space-saving compact systems at a favourable

all-inclusive price!

???? LiSEC´s industry leading knowledge base: LiSEC Advice, LiSEC Software,

LiSEC Service

Fit for your individual demands!